Introduction

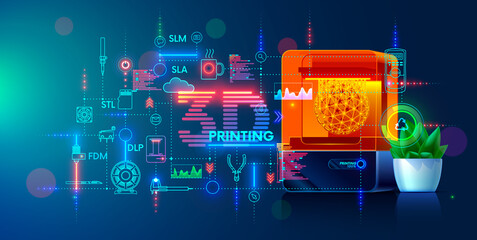

3D printing is a technology that has revolutionized the manufacturing industry. The ability to produce physical objects from digital designs has transformed the way products are designed and manufactured. The technology has been around for several decades, but it is only in recent years that it has gained significant momentum and become widely adopted across industries. In this article, we will take an overview of 3D printing technology and its evolution, including its history, development, and future potential.

History of 3D Printing

The concept of 3D printing dates back to the 1980s when Chuck Hull, the founder of 3D Systems, first invented the process of stereolithography. This involved using ultraviolet light to cure liquid resin, and building up layer by layer to form a solid object. Over the following years, other 3D printing techniques such as fused deposition modeling (FDM) and selective laser sintering (SLS) were developed, each with its own unique benefits and limitations.

Development of 3D Printing

Since its inception, 3D printing technology has come a long way, with significant advancements in the materials, machines, and software used in the process. One of the major developments in the industry has been the introduction of new materials, including metals, ceramics, and composites. These materials have allowed 3D printing to be used in a wider range of applications, including aerospace, medical devices, and consumer products.

In addition to the development of new materials, there has also been significant progress in the machines used for 3D printing. The introduction of industrial-grade 3D printers has allowed companies to produce high-quality parts on a large scale, while the development of desktop 3D printers has made the technology accessible to individuals and small businesses.

The Impact of 3D Printing

3D printing has had a profound impact on the manufacturing industry, with the technology being used for everything from rapid prototyping to end-part production. The ability to produce parts quickly and efficiently has reduced lead times and improved the speed of product development. In addition, the flexibility of 3D printing has allowed companies to explore new and innovative designs, leading to the creation of new and exciting products.

Another benefit of 3D printing is the ability to reduce waste and improve sustainability. The additive nature of the technology means that only the material required to produce the final product is used, reducing the amount of scrap material generated compared to traditional manufacturing methods.

Challenges and Limitations of 3D Printing

Despite its many benefits, there are also some challenges and limitations to consider with 3D printing technology. One of the main limitations is the size of the objects that can be produced, as 3D printers typically have a limited build volume. In addition, the cost of 3D printers and materials can be high, making it difficult for smaller companies to invest in the technology. Finally, the quality of the final product can be limited by the resolution and accuracy of the 3D printer, although this is improving rapidly as the technology continues to evolve.

The Future of 3D Printing

The future of 3D printing is incredibly promising, with technology continuing to improve and become more accessible. The development of new materials, machines, and software will continue to push the boundaries of what is possible with 3D printing, leading to new applications and industries being transformed. In addition, the decentralization of manufacturing and the ability to produce custom and personalized products could also have a significant impact on the global economy, creating new opportunities for growth and innovation.

Conclusion

3D printing technology has come a long way since its inception and has had a profound impact on the manufacturing industry. The ability to produce physical objects from digital designs has transformed the way products are designed and manufactured and has reduced lead times and improved the speed of product development. However, there are still some challenges and limitations to consider, such as the size of the objects that can be produced, the cost of 3D printers and materials, and the quality of the final product. Despite these challenges, the future of 3D printing is incredibly promising, with technology continuing to improve and become more accessible, and with new materials, machines, and software pushing the boundaries of what is possible. The decentralization of manufacturing and the ability to produce custom and personalized products could also have a significant impact on the global economy, creating new opportunities for growth and innovation.